About me

Interests

A little personal background before we get into my experience

Photography

I have found fulfillment in letting out my creative side through the art of photography. Everything from engaging with my subjects to pushing the boundaries of my technical abilities has been exciting for me. Here are a few of my favorite shots.

Sports

I frequently enjoy spirited physical activities such as basketball and other team sports. Most recently, I have enjoyed running a Spartan Race with some friends.

Travel

Studying abroad over the course of my college career has exposed me to a plethora of new ideas and kindled a love of travel within me.

Space

I have been fascinated by the cosmos and the potential for scientific discovery outside of earth for most of my life. Creating this timelapse of the Milky Way Galaxy has also sparked my interest in optics and telescope technology.

Research

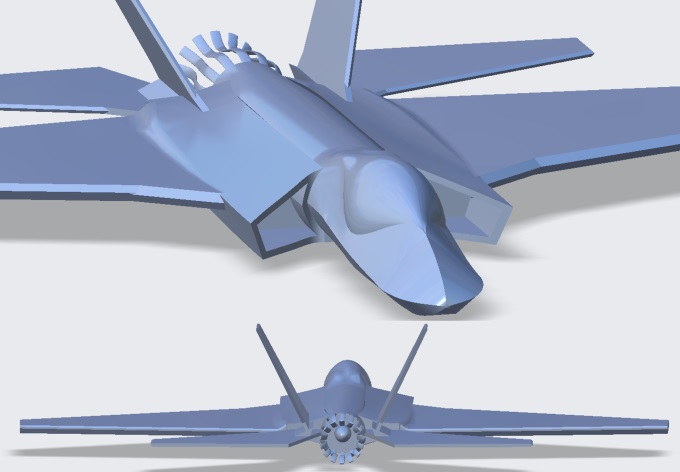

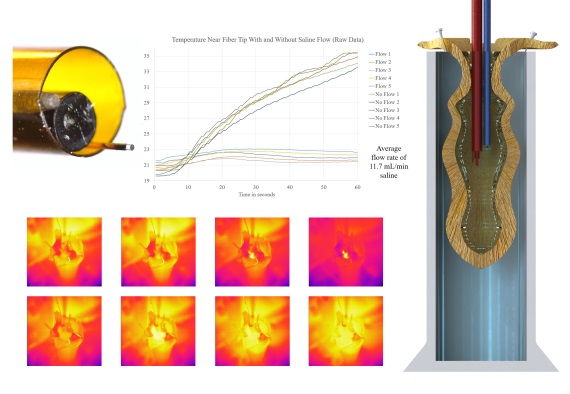

A small summary of all of my research projects at school.Miniature endoscope study

Using a testbed setup with a thermocouple, a thermal camera, and porcine tissue, I performed verification and validation

experiments to prove the viability of an experimental miniature endoscope. I also created realistic 3d models of the setup

and generated the graphics for the SPIE Advanced Photonics in Urology conference paper.

Skills gained: Testbed Sensor Integration, 3D Modeling/Rendering, Experimental Troubleshooting, Data Acquisition

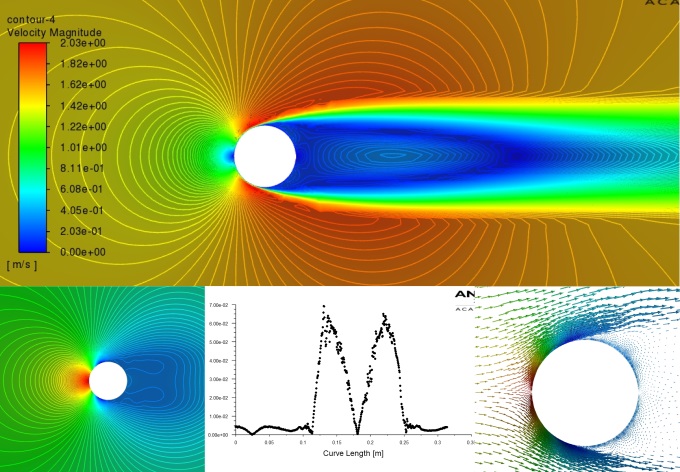

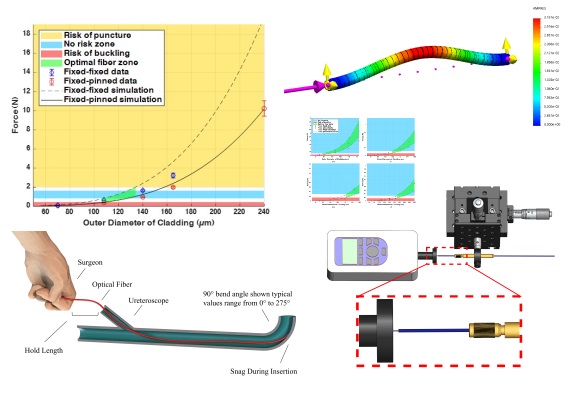

Simulation Fiber Strength Study

Using Solidworks FEA, I simulated buckling of fibers on the micron scale and then verified those simulations with a

benchtop study. I wrote data visualization scripts using MATLAB. This study had direct applications in the

medical field for ureteroscopy. After writing a conference paper for SPIE Photonics West, I continued editing it to

get it peer reviewed into the journal Optical Engineering.

Skills gained: FEA, MATLAB, Technical Writing, Verification Testing, Data Analysis

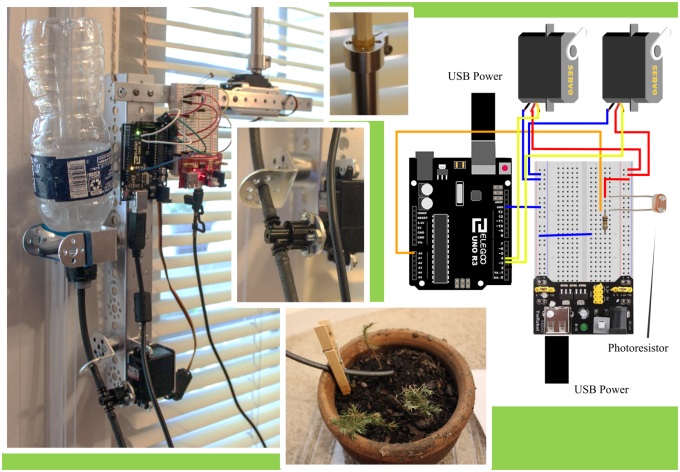

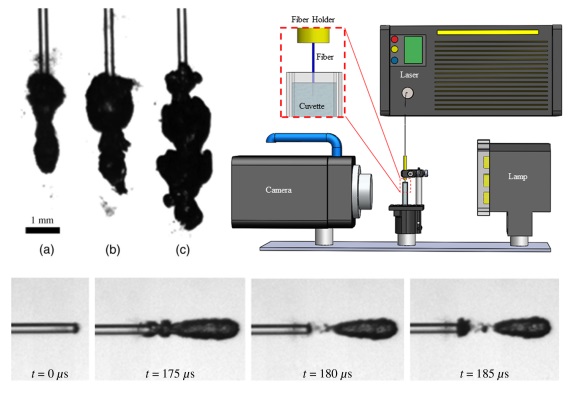

High Speed Analysis of Surfactant Around Vapor Bubbles

This unique study required use of a creatively designed electronic test equipment setup to effective trigger

a high-speed camera to capture the vaporization of liquid after a laser pulse. At 200,000 frames per second,

any delay in the triggering process would have incurred tedious amounts of data acquisition for a laser

pulse as small as 250 μs. My work included test setup, data acquisition and analysis, and equipment

troubleshooting.

Skills gained: Electronic Test Equipment (Function Generator, Oscilloscope, Trigger, Thulium Laser), Test Setup Troubleshooting

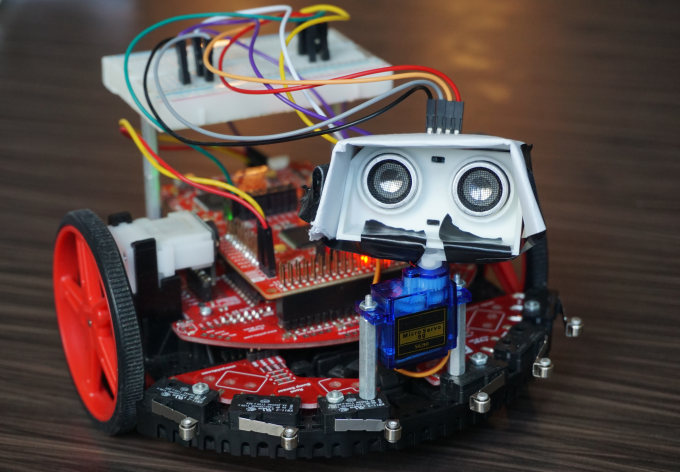

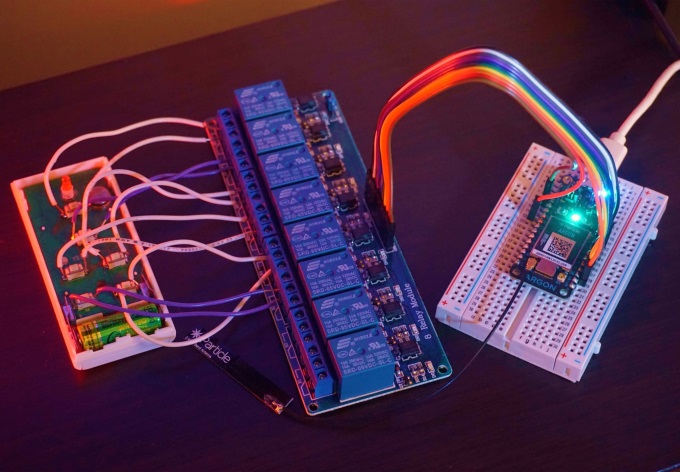

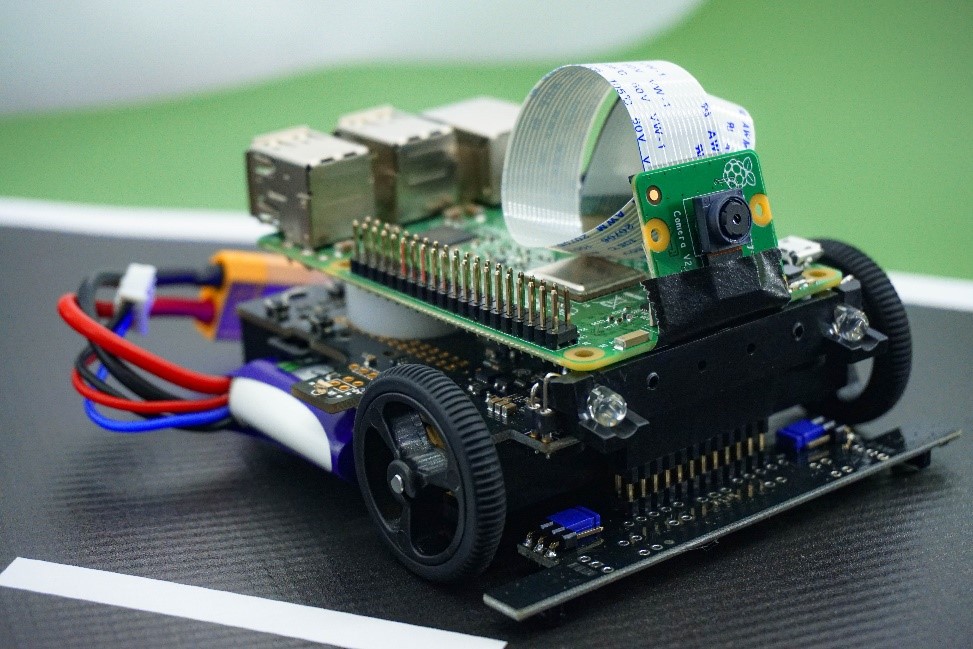

Multi-agent Smart City Robotics

With the development of 5G communication and smarter vehicle technology, research into smart city integration has gained major scalable potential.

I worked with Dr. Amir Ghasemi to lay the foundation for future machine learning, IoT incorporation and smart infrastructure research using a

multi-agent robotics cluster (with Lidar, vision, light, and ultrasonic sensors in addition to mesh communication) and a scaled city

simulation environment. My role included groundwork research into the tech required to create this robotics cluster and direct

implementation and construction of the scaled city model.

Skills gained: Electronic Robotic Component Integration, Scale Modeling/Design

Industry Experience

Human Factors Design Intern

The National Aeronautics and Space Administration, Huntsville AL Jun 2022-Aug 2022

Working at NASA gave me an appreciation for the incredible levels of communication and collaboration that are required

to design complex aerospace systems. After speaking with every NASA engineer who was willing to talk, I learned that

I would love a role in systems integration. The combination of the people skills needed to interface with multiple large

teams and the technical skills needed to understand the entire system is a perfect combination for my personality type

and working disposition.

My Roles:

-Using persistent problem solving methods to convert a model of a vertical deep space habitat from SketchUp into .jt file format using Siemens NX.

Optimizing the model for VR (virtual reality) analysis in Siemens Process Simulate

-Modeling an EVA helmet with accurate maximum FOV ranges for human factors analysis using Creo Parametric

-Creating detailed 3D models of multiple MSFC buildings and internal habitat mockups to be used by center management to plan future habitat work at MSFC

-Optimizing building models for VR (VIVE Pro 2) and AR (HoloLens) to assist with visualization of the different habitat layout options

-Collaborating with engineers across the Human Factors Engineering group to produce a promotional tour video describing the utility and capabilities of the EV74 Virtual Environments Laboratory (VEL)

-Interfacing with engineers and designers facilitating the use of VR for the Mars Ascent Vehicle (MAV) Technical Interchange Meeting

-Preforming a small human factors analysis on the Mars Transit Habitat med bay area

Skills gained: Human Factors Analysis, 3D Modeling/Rendering, Virtual Reality Application, Augmented Reality Application

ME Testing and Analysis Co-op

General Dynamics Mission Systems, Greensboro NC June 2021-Jan 2022

At General Dynamics, I gained the most impactful hands-on experience of my college career.

Being a part of the team that operated near the end of the engineering process for mission

deliverables (testing) allowed me to see the importance and direct implications of all

of the previous stages of engineering (such as system planning, design, review, and manufacturing).

In addition to gaining hands-on integration and testing experience in unique testing facilities, I was also

able to take note of how I could be more effective in other roles (such as design and quality

assurance) when my team was faced with challenges because of the nature of inefficiencies in large multi-team projects.

My Roles:

-IP camera system setup, debugging and integration

-Planning, Designing and acquiring materials for a 60-ft long 6-ft high launching stage for deliverable components then leading a team in its construction

-Analyzing sensor data from over 120 sources (such as pressure transducers, torque sensors, Accelerometers etc) and footage of test events for design improvement

-Testing and validating full system mission critical machinery to meet shock response spectrum and integration requirements

-Using engineering drawings to make design adjustments on a complex hydraulic system

-Honing time management skills by juggling tasking from several different teams

-Directly learning from Machinists, Technicians, Engineers, and Scientists about proper engineering techniques and methods

Skills gained: Testbed Sensor Integration, 3D Modeling/Rendering, Experimental Troubleshooting, Data Acquisition

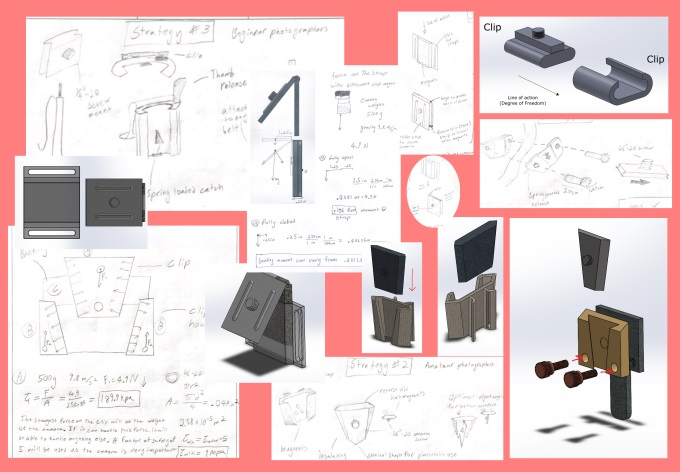

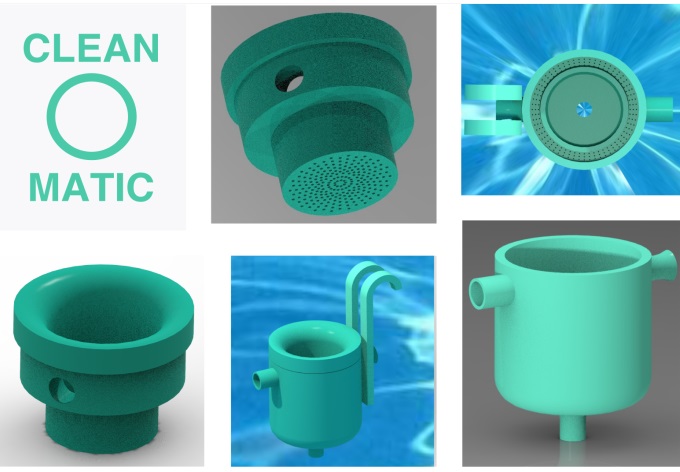

Product Development Intern

Enventys Partners, Charlotte NC Dec 2019-Jan 2020

At Enventys Partners, I worked with industrial designers, engineers and machinists creating

proof of concept prototypes for patent applications and future market use. I learned how to

operate an industrial waterjet cutter, and other various fabrication tools. I gained hands on

experience with an accelerated design to fabrication process.

My Roles:

-Fabricating prototypes

-Testing potential product designs for fit and reliability

-Assembling final demonstration products

Skills gained: Waterjet Cutting, Laser Cutting, Milling, Lathe Machining, Plastic Part Design, 3D Printing

Project Engineer

WindAid, Trujillo Peru June 2019-Aug 2019

WindAid is a unique nonprofit organization that focuses on providing reliable

and sustainable energy sources to remote communities in Peru. The entire experience

was incredible; I was immediately immersed in the Peruvian culture and pushed out

of my comfort zone. While working around the language barrier, I got hands on with

the construction of a 20 ft 500 Watt turbine from raw components like rebar and copper

wire. I was also able to improve the design of a vacuum chamber for turbine blade creation.

The experience concluded with my team going into the remote community of Jesús María Peru to

install the turbine and meet the locals.

My Roles:

-Welding frame and base components

-Coordinating team movements to facilitate efficiency

-Fabricating turbine blades

-Assembling final wind turbine on site

Skills gained: Arc Welding, Resin Composite Molding, Electromagnetic Coil Winding